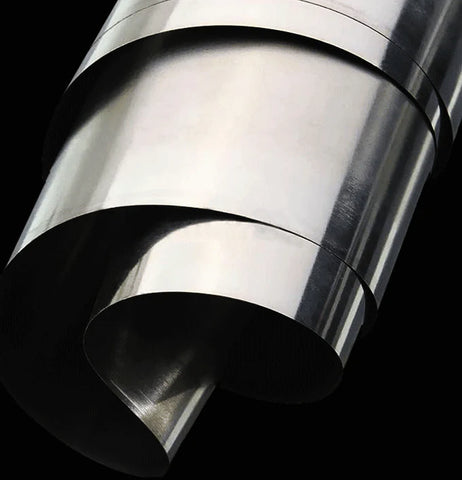

Thin Metal Cutting

Minimizing Material Waste for Cost Savings and Eco-Friendly Results

Laser cutting is efficient in terms of material usage. The narrow cutting width and minimal kerf (the width of the cut) result in less material wastage compared to other cutting methods like traditional machining or stamping. This not only reduces costs but also makes it environmentally friendly.

Our laser-cutting techniques can handle a wide range of materials, including stainless steel, aluminum, brass, copper, and more.

When the fit isn’t just right, we can help. Our facility can fabricate shims at variable sizes to suit your exact specifications and can be as thin as .002 inches.

Shims can be made of aluminum, brass, copper, stainless steel, full-hard steel, and half-hard steel.

UNLEASH YOUR CREATIVITY

Laser cutting offers boundless potential for innovation and artistic expression. Let us transform your visions into reality!